BEAST KNOWHOW

What can we do that the others can’t? What distinguishes our components from others? The answer lies in our origins. We at Beast Components aren’t just bike nerds; we’re experts in lightweight construction. Our know-how means that we can get the absolute best out of carbon.

CARBON SKILLS

Carbon is our passion. We often wonder where the bad image of carbon components for bikes comes from. The only way we can explain it is that it results from bad carbon components. This image saddens us, because carbon has a huge range of fascinating properties.

Carbon is a fibre composite material that is used in countless industries. Its use is also booming in the bike industry. A composite material combines two materials to unite the positive properties of both. In the case of carbon, these two materials consist of the carbon fibres and the corresponding epoxy resin as an “adhesive”. This combination becomes extremely sturdy, while remaining incredibly light.

There are several advantages to carbon. It has a high fatigue strength, is super-sturdy, stiff, does not corrode and offers an enormous design freedom. However, carbon is anisotropic. This means that it is capable of absorbing loads primarily in the fibre direction and less in cross direction. It also absorbs tensile forces in fibre direction much better than it does compressive loads. It is therefore necessary to orientate the fibres in the component in accordance with the load direction. Experience in design, construction and manufacturing is essential, as well as type and quality of the materials used. Thanks to the cooperation with our development supplier Realize Engineering (specialized in aerospace) as well as various research projects with the Institute for Lightweight Engineering and Polymer Technology at the TU Dresden and companies in the aviation industry, we have expert knowledge and are familiar with the current state of the art to an extent beyond anyone else in the bike industry.

There are an unbelievable variety of carbon fibres available. There are different fabrics, non-crimp fabrics and many mixed forms. Each has its own characteristics, so it is important to use them correctly. In the bike industry, there are mainly three different carbon bindings: twill weave, plain weave and uni-directional non-crimp fabric (UD-NCF).

Plain weave and twill are fabrics in which the carbon fibres are not ideally stretched, but have regular, short-wave curvatures. This waviness is known as “crimp”. Increased curvatures reduce the mechanical properties, since complex stress conditions prevail where the threads cross one another.

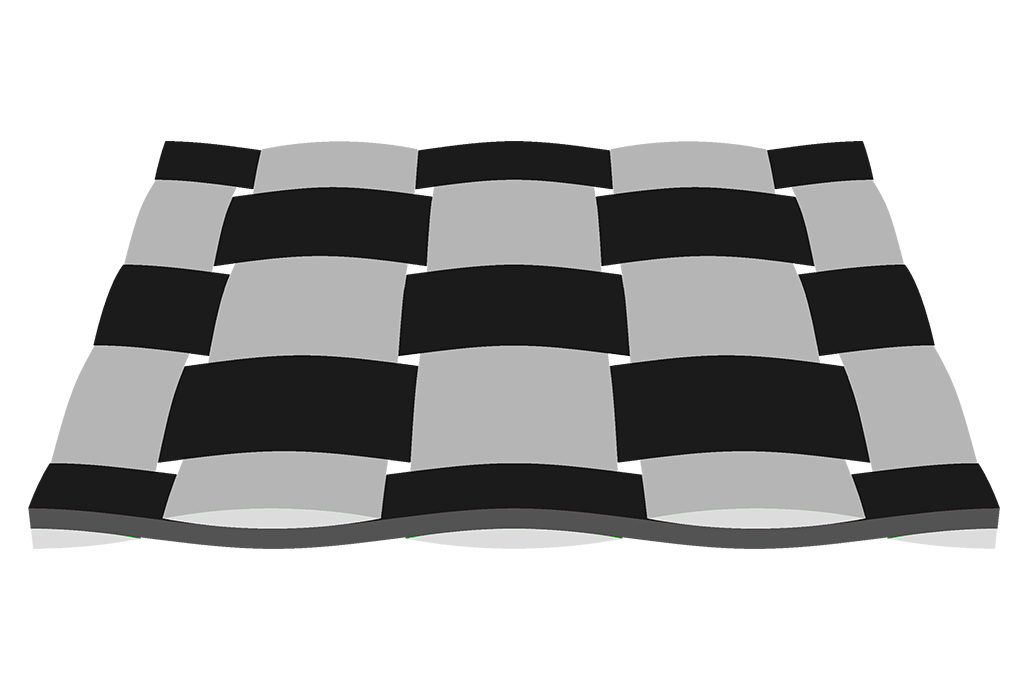

In plain weave, a single weft thread runs alternately over and under a single warp thread. Due to the harsh fibre curvature, plain weave has the worst compression and fatigue strength values among the fabrics mentioned above.

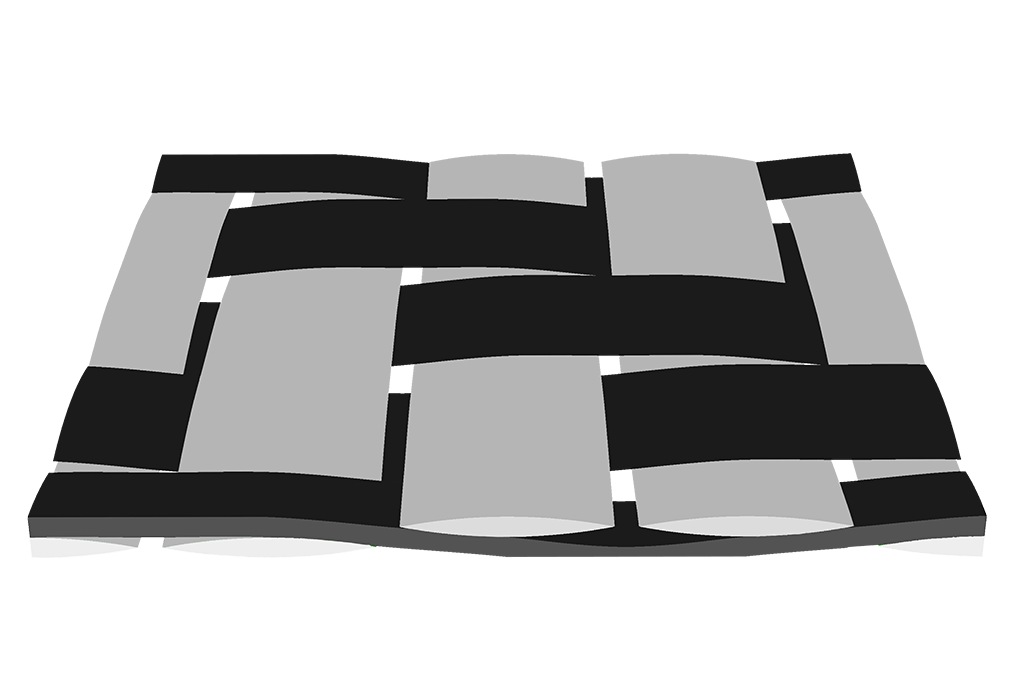

In twill 2/2 weave, one weft thread runs alternately over and under two warp threads. The carbon fibres are therefore stretched to a greater extent than in plain weave. Twill weave is therefore more resistant to slipping and is also easier to drape.

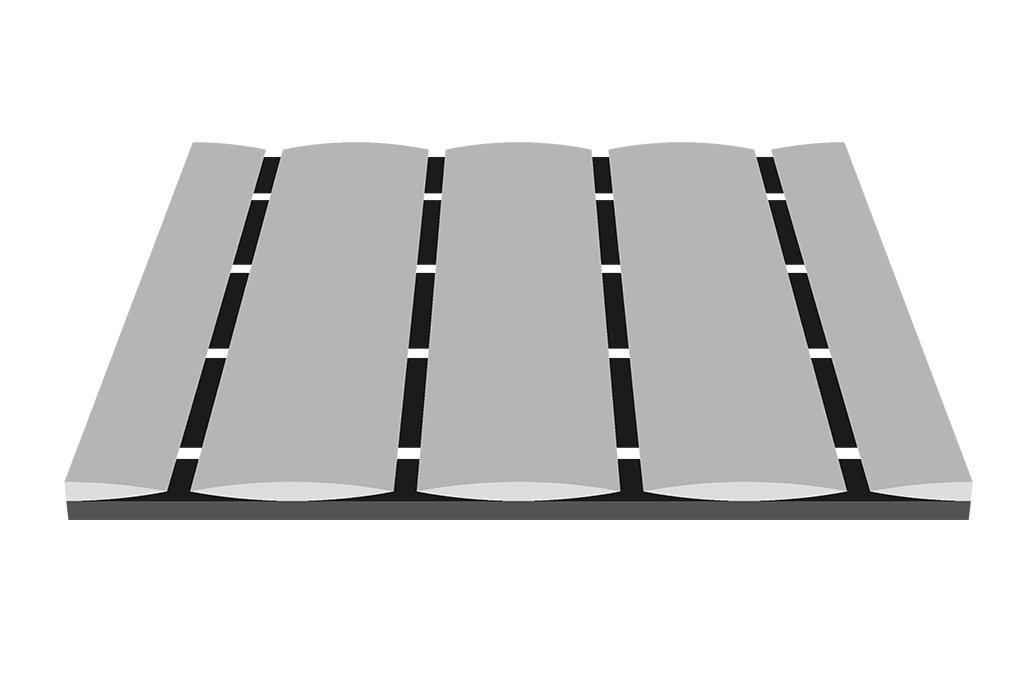

However, maximum stiffness and strength can only be achieved using stretched fibres. This is where the strength of non-crimp fabrics (uni-directional – UD) comes from. The special feature of UD is that the individual fibres are aligned in a single direction only (uni-directional). The carbon fibres are therefore stretched, which in turn leads to significant higher stiffness and strength. However, the fabric is much more complicated to work with and requires a lot of care during when laying up.

We have decided to produce our components in two different looks: the UD finish and the SQ finish. We use UD fabrics almost exclusively. This is due to their high level of stiffness. For the SQ finish we use an additional cover layer with plain weave (spread tow). We ensure that the stiffness of the top layer is adapted to the UD laminate underneath.

We accept the fact that production is more laborious because UD non-crimp fabric does not drape as easily. What counts for us first and foremost is the significantly higher strength.

HIGHEND ENGINEERING

For us, too, everything begins on a blank sheet of paper. First, we note a few ideas regarding design and our engineers consider the specifications that the component must fulfil, using as their basis the requirements of the toughest industrial tests. This is because carbon components for bikes must be able to withstand enormous forces and, of course, must not break. Our design engineers start work using these specifications. They design and develop the component using the CAD software CATIA. The moulds for our components are also derived from this.

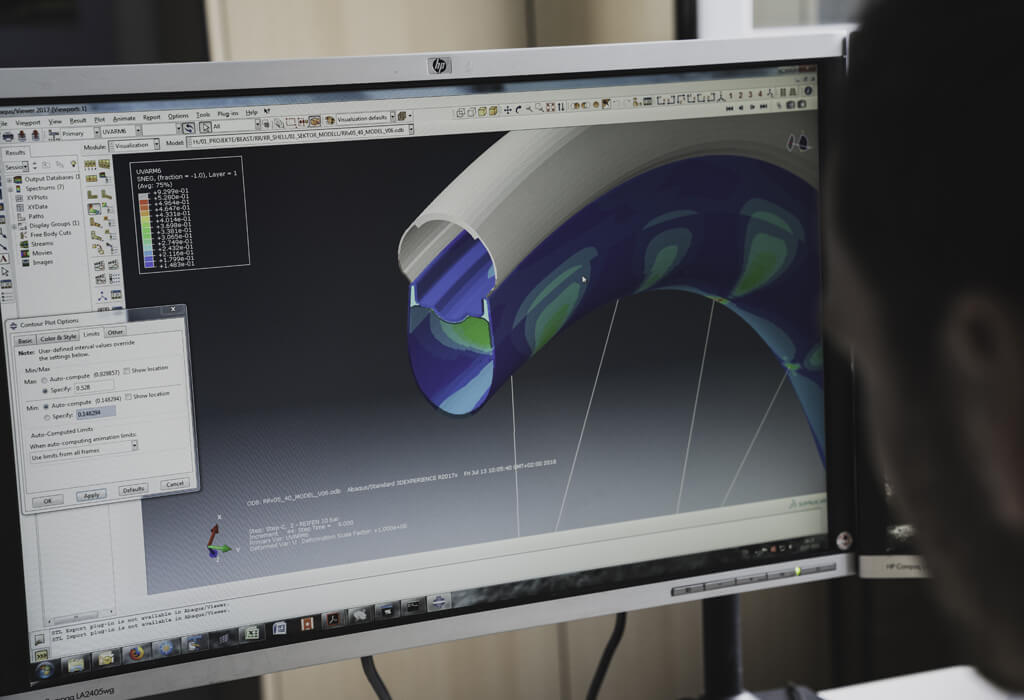

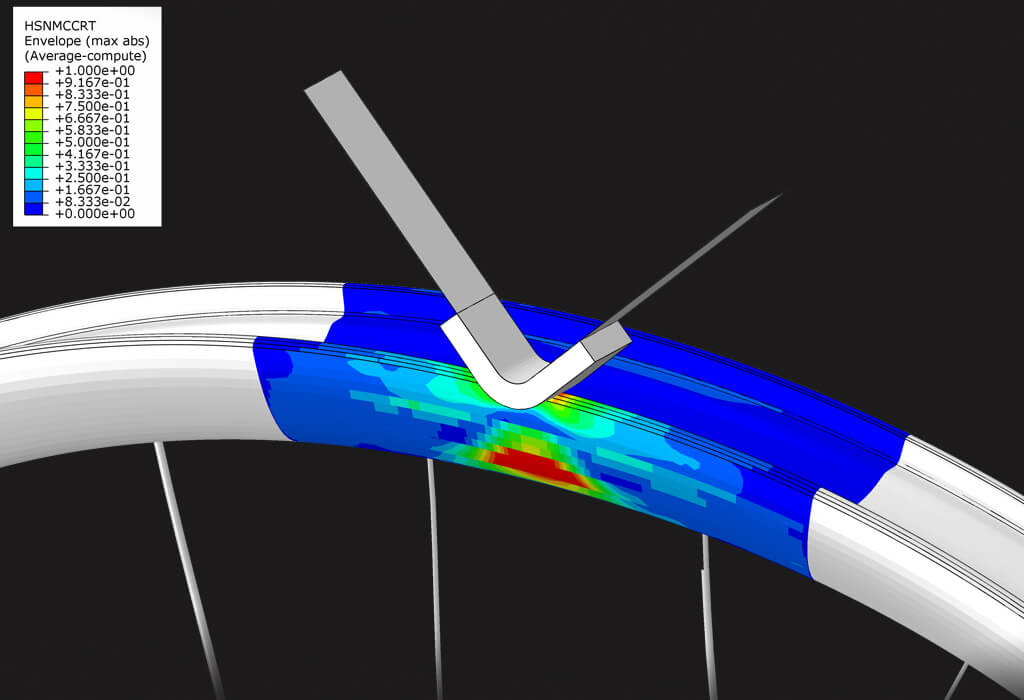

A major highlight of our development is the complex simulation of each individual component using the FEA software ABAQUS. For the most part, non-linear calculations are performed using fracture-mode-related failure criteria (Cuntze criterion) and evaluated using downstream S/N curve systems (Wöhler). The result of this is that we can virtually test the strength and deformation properties of components under specific loadings and predict a defined life-time before production even starts. Our handlebars, for example, are simulated concerning cyclic loadings, while the rims are examined in a virtual crash simulation. This allows fast development without unnecessary design loops. As a result of these often complex simulations, we receive precise layup plans that are optimized for the respective loads. We then build prototypes and test them on our own test stands to validate the simulation results.

Thanks to this scientific approach to component design we can reach the limits of what is physically possible, because we know exactly where those limits are. This approach is an absolutely unique selling point within the bike industry.

PRECISE PRODUCTION

We work using the best-known lightweight engineering process for complex components: the prepreg autoclave process. First, every layer of the pre-impregnated semi-finished fiber, the so-called “prepregs”, is mechanically cut to the correct fit.

The next step is laminating, i.e. laying up the individual carbon layers in the moulds. This requires considerable skill, accuracy and experience. Every single component is created layer by layer. We use a lot of thin carbon layers, which makes production more laborious. The following will give you a better idea of how the lamination process works: Depending on the handlebar, up to 84 prepreg plies must be positioned by hand according to a specific plan.

After the technicians have very carefully placed the prepregs in the mould by hand and in the appropriate sequence, everything is vacuum-sealed for curing in our autoclave. The components cure under pressure, a constant vacuum in the tool and temperatures of between 110°C and 150°C. This prevents from inclusions (pores) and fluctuations in quality.

The parts are demoulded by hand and meticulously checked. The handlebars is examined for defects or unevenness. Only components that are perfect in terms of construction are then subjected to visual quality control.

During the visual inspection, components with defects such as bubbles, dents or folds are separated. The tiniest visual defects, unrecognizable to the untrained eye, are repaired, prepared and finished. We do this because our customers expect, and we want to supply, absolutely perfect components.