BEHIND THE SCENES

AT OUR TEST LABORATORY

Thanks to our extensive simulations using the finite element method during the engineering process, we know the capabilities of the first prototype even before the first test. This is a unique procedure within the bike industry and is our targeted method of determining further development. We don’t need the usual trial and error procedures.

But we want to push the boundaries and make components as light as possible and super-sturdy. Test stands are absolutely essential here. Our testing is crucial to our development and re-development process. But its most important effect is on the continuous quality control of our products and the validation of our FEM simulations.

No simulation or test can replace reality, of course. We have a large number of experienced riders to put our products through their paces and give us direct feedback on the riding characteristics.

We test far beyond the minimum legal requirements. We see a special challenge in enduro and downhill, because there are enormous forces acting on the components. But we want you to trust our components 100%, no matter what kind of biking you’re into.

UNIVERSAL PNEUMATIC TEST STAND

This test stand offers a whole universe of possibilities. It’s an all-rounder and we use it every day for our components – handlebars, stems, seat posts and spokes.

> HANDLEBARS AND STEMS

The handlebar is attached to the test stand together with the stem. Hydraulic cylinders are fixed to both ends of the handlebar. These cylinders are used to provide a realistic force application with tension and compression. As in the real world, this creates in- and out-of-phase loading. Compression builds up when you jump; you pull on the handlebar when you ride out of the saddle.

We use a defined test cycle with various test blocks consisting of 6 load situations (just like the tests conducted at renowned testing institutes):

> SEAT POSTS

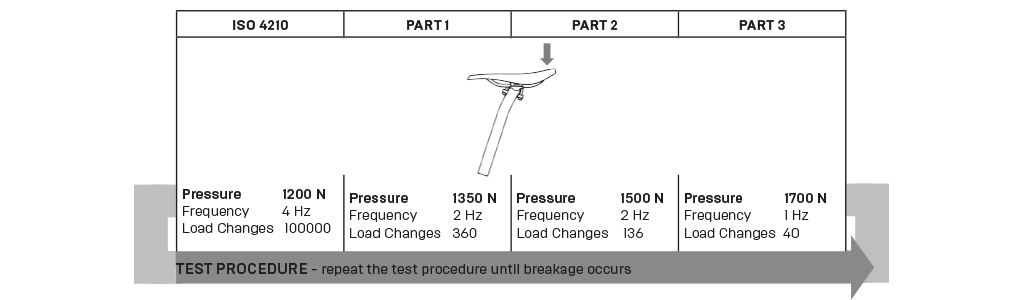

The seat post is attached to the test stand with a seat angle of 73°. The force is applied 70 mm behind the center of the seat clamp. First, the seat post must pass the standard test according to ISO 4210 followed by a defined test cycle consisting of three additional blocks:

> SPOKE PULL-THROUGH TEST

The spoke holes are critical areas of a rim and require extra attention. We use the spoke pull-through test to quantify the force a rim can withstand in the area around the hole. We use both – a static and a dynamic test. In the static test, a spoke is tensioned through the same hole 10 times in a row until the spoke breaks (max. 3200 N). The following dynamic test simulates 500 load cycles at 0.5 Hz with an increasing tensile load of up to 2000 N. Spoke rupture may even occur, too. The rim, however, must not show any signs of damage.

> STIFFNESS TEST

We use the stiffness test to quantify the flexibility of our handlebars and seat posts. This test gains feedback about the comfort of our components.

IMPACT TEST STAND

The impact test triggers a fracture of the rim flange. There are various test setups in the bike industry. In order to ensure comparability between the wheels, it is important that always the same conditions prevail in every test. We have decided to use the following experimental setup, which we believe is the most realistic:

– fully spoked rims

– same tire according to the category (e.g. Magic Mary for MTB)

– same tire pressure (1.6 bar)

– no angle of attack

In the experiment, an anvil with weights is dropped onto the wheel from a predefined height. The higher the drop position, the greater the resultant force. The wheel is gradually subjected to heavier impacts at different points – until it breaks.

During rim developing, it is important to us that a small failure does not lead directly to complete fracture. Damage tolerance and slow growing failure after impact (benign failure) is essential for safety. Sufficient residual stiffness must be guaranteed after the rim breaks for being able to stop safely. However, we want to push the limits and require that our wheels are capable to get you home even if you break them.

ROLLER TEST STAND

We use the roller test stand to perform an operational load test that subjects every of our wheels to the forces close to them when riding. The test is adapted to the conditions prevailing in the application, depending on the wheel type. The wheel types are affected by different weights, speeds and obstacles. The obstacles vary in number and height, providing realistic loads as they occur while riding.

After 125.000 revolutions, the wheel has overcome a total of 750.000 obstacles. If the rims and spokes remained intact, the wheel has passed the test.