Technical Details

| Material | Carbon |

| Range of Use | XC | Trail | Enduro | Downhill |

| Price | UD-Finish black: 199.90 € SQ-Finish black: 219.90 € UD- and SQ-Finish colored: 299.90 € |

| Clamp Diameter | 31.8 mm | 35 mm |

| Width | 800 mm |

| Rise | 25 mm |

| Backsweep | 8° |

| Upsweep | 5° |

| Weight 31.8 mm | UD-Finish: 206 g SQ-Finish: 217 g +7 g with color |

| Weight 35 mm | UD-Finish: 217 g SQ-Finish: 228 g +7 g with color |

| Weight Tolerance | 5% |

| Weight Limit | none |

| Colors | UD- and SQ-Finish: black | red | blue |

Our Riser Bar is not only more stable than its competitors, but also noticeably more comfortable. It significantly dampens small shocks and vibrations better by using the highest quality materials and its sophisticated carbon layer plan. At the same time, it is stiff enough to give you the right feedback and lets you manoeuvre very precisely.

DESIGN & INNOVATION AWARD 2022 – WINNER

“The Riser Bar [2.0] carbon handlebar from Beast Components is made for the toughest enduro tracks and downhill use, capable of holding its own where other carbon handlebars fail. Many brake levers on the market use narrow clamps that aren’t perfectly round, concentrating the clamping forces on small surface areas. Designing the clamps this way leads to poor load distribution and can damage carbon handlebars by making dents. The Riser Bar [2.0] prevents this with a special polyester prepreg fleece and appropriate carbon layup. It can withstand up to 6 Nm torque on brake clamps, which is twice as much as an ordinary carbon handlebar can handle. As such, when you have to tighten your brake levers on the trail without a torque wrench, you won’t easily run the risk of damaging the handlebar. Despite the increased durability, the Riser Bar remains in the flyweight category, topping the scales at just 174 to 234 g, depending on the model. The handlebars are handmade entirely in Germany and add a special touch to any bike with their perfect finish. They’re available in a wide range of widths, a 31.8 or 35 mm diameter and 15, 25 or 35 mm rise. You’re sure to find a Riser Bar that suits your needs.”

Award Jury Verdict

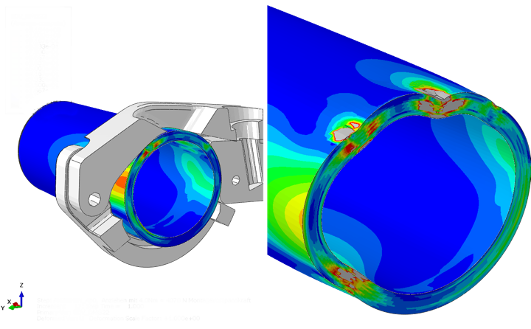

WHY WE HAD TO MAKE ADJUSTMENTS

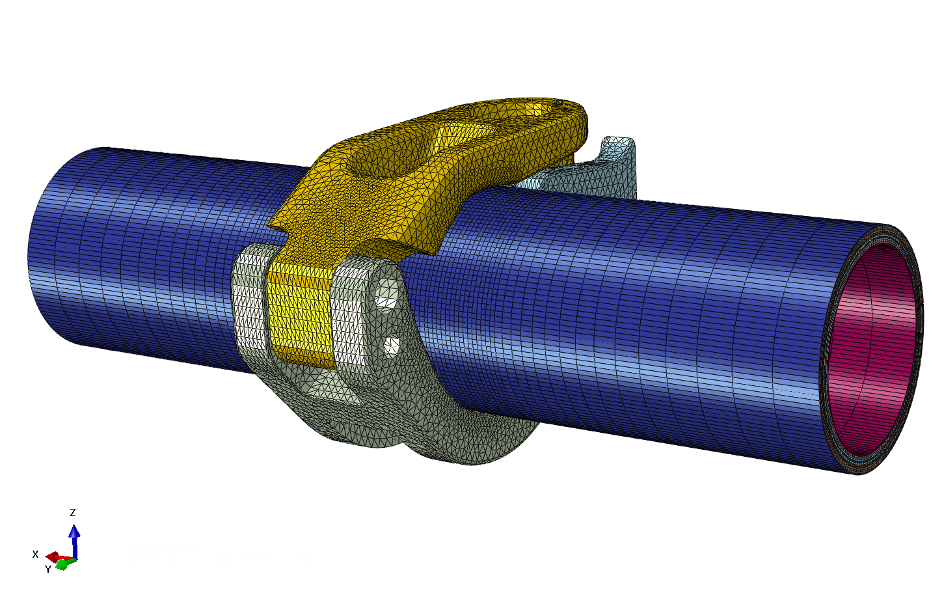

Some new brakes and clamps on the market (including those from Shimano and SRAM) have a very unfavorable clamp design for carbon and lightweight handlebars. The clamps are not round and the contact surface is minimal. Loads are thus no longer distributed evenly over the clamping area of

the handlebars, instead applied en point. This squeezing principle of the new brake clamps is pure poison for any carbon structure. You don‘t have to be an engineer to understand that loads acting like this on the handlebars cannot be distributed in an appropriate way. Thanks to our close cooperation with Realize Engineering, a development service provider specialized in high-tech lightweight construction, it was no problem to take a closer look at the most common brakes on the market. The results were alarming.

We have spoken with the affected manufacturers and informed our customers about the issue. We have considered blocking the affected brakes and clamps for our MTB handlebars. Nevertheless, in the end we have found that we have to live with the new clamp designs. That‘s why we searched for a solution, found one and implemented it immediately.

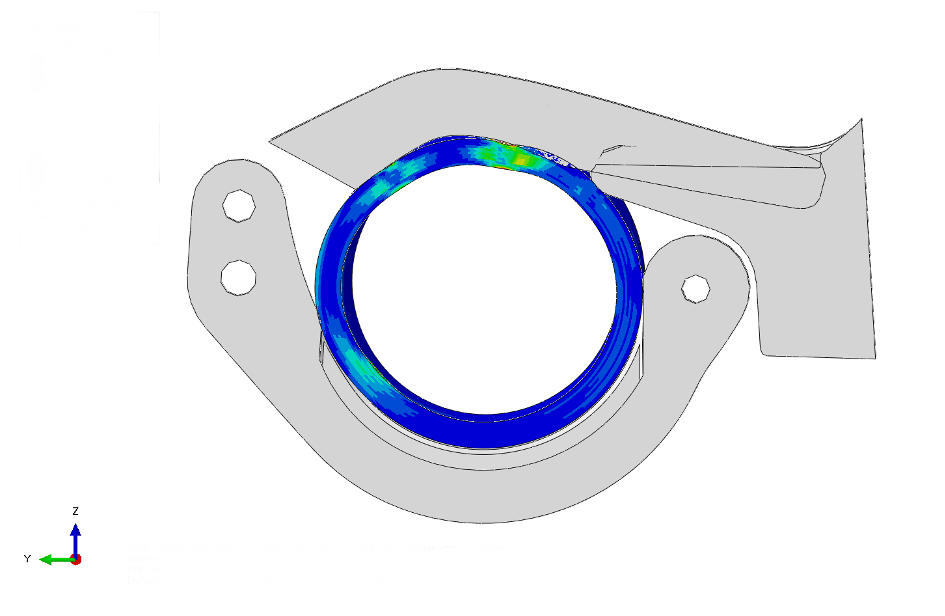

THAT´S NEW

To achieve even greater safety and fatigue strength, we have once again looked at the structure of our handlebars in the clamping area of the brake levers. In addition to the new and even more sophisticated and load-oriented layer structure and a very elaborate fiber arrangement, we now use a special polyester prepreg mesh for our Riser and Flat Bars. This polyester prepreg mesh has the following positive properties for us: It has a high strength and retardation and at the same time a low sliding friction and great durability against wear due to sliding action.

We used it exclusively in the clamping area of the brakes. Thus, point loads are absorbed much better and distributed evenly over the handlebars. Impressions of the clamps are reduced to a minimum and the carbon layers underneath are protected. It is a safety buffer to the pressure-sensitive carbon surface and allows the free selection of the desired brake and the use of a higher tightening torque.

SAFETY COMES FIRST

The polyester prepreg mesh we use blends discreetly into the appearance of the handlebars, yet breaks through the fiber structure. If fittings and grips are installed, the new clamping area is hardly noticeable. We accepted the visual change and the extra weight of about 20 g compared to the old models, because it provides our and your customers with more safety. And that‘s what it should come down to.

To achieve this new level of safety we have established a more extensive test procedure. Thereby, the new Riser Bar 2.0 and Flar Bar 2.0 models must pass an extended and above all more realistic Multi-Load test than before. It includes, for example, twisting the brake clamps five times with a tightening torque of 1.5 Nm and tightening and loosening the brake clamps ten times with a tightening torque of 4Nm before the actual test starts